The pre-heated charge is fed into the EAF where it is melted by the liquid steel in a continuous cycle. This permits constant flat bath operation, a key advantage over conventional batch processes where scrap is melted directly by the electric arc. The EAF gases are sent to a fume-cleaning plant where carbon monoxide and pollutants are burned in a combustion chamber without consuming fuel. The system uses heat from the flue gas for cogeneration of hot water and/or steam.

The Consteel system technology simplifies steelmaking logistics by minimizing scrap movements. Furnace bay crane activities using charge buckets are virtually eliminated, for lower operating and maintenance costs. Leakages in the water-cooled furnace sidewalls, roof and lances caused by arcing or scrap impact are avoided, thus minimizing the risk of water entering the furnace. The Consteel equipment is designed for high reliability and low maintenance, including reduced refractory maintenance. The result is a safer, more congenial working environment compared to typical conditions in the steel industry.

The ConsteeI system satisfies key melt shop requirements in the minimill business:

- Fast payback

- High Flexibility

- Low production costs

- Reduced environmental impact

- High productivity

- Personnel safety

Improved Environmental Sustainability

The Consteel system reduces workplace noise and dust and eliminates bucket charge operations. The absence of charge buckets minimizes dust formation in the canopy hood, while the pre-heating section of the conveyor acts like a deposit chamber, allowing dust to settle on the scrap for recycling inside the furnace. Overall dust emissions are 5 - 9 kg/tls lower than those of a conventional top-charged EAF. The reduction of total energy required for melting has a tremendous impact on the reduction of GHG (Greenhouse Gases) emissions. Consteel provides the most environmentally friendly technology available on the market, with the ability to meet strict government regulations.

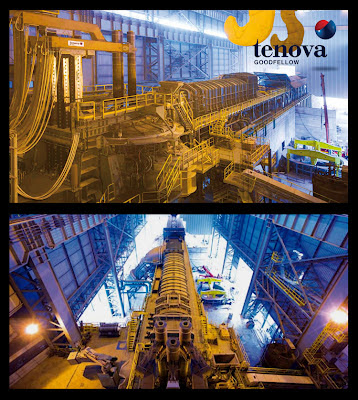

Addendum Jan 28, 2013 - here are a couple more pictures of Tenova CONSTEEL installations:

Consteel is the choice of steelmakers worldwide. If you are a steel maker interested in higher productivity and lower costs, contact Tenova Goodfellow for more information about the award-winning CONSTEEL® system.

Tenova GOODFELLOW

Fax +1 905 567 3899

goodfellow@ca.tenovagroup.com

For information on gas analyzer systems, give Mike or Dave at Nova a call, or send us an e-mail.

1-800-295-3771

sales at nova-gas dot com

websales at nova-gas dot com

If you have a LinkedIn account, search for Nova Analytical Systems under Companies and follow us if you want.

_

No comments:

Post a Comment